When it comes to optimizing your warehouse operations, understanding how to maximize the capabilities of your forklift is essential. One of the most effective ways to enhance your lift’s performance is by utilizing fork lift extensions. These invaluable attachments allow you to handle longer and heavier loads, making your equipment more versatile and efficient. If you’re looking to improve your productivity and streamline your material handling processes, exploring fork lift extensions could be the game-changing solution you need.

In this comprehensive guide, we will delve into the various types of fork lift extensions available, their benefits, and how to properly use them to ensure safety and efficiency. Whether you are a warehouse manager or an equipment operator, knowing how to effectively utilize fork lift extensions can lead to better inventory management and ultimately, a more successful operation. Get ready to unlock the full potential of your forklift and expand your reach in the workplace.

Understanding Forklift Extensions

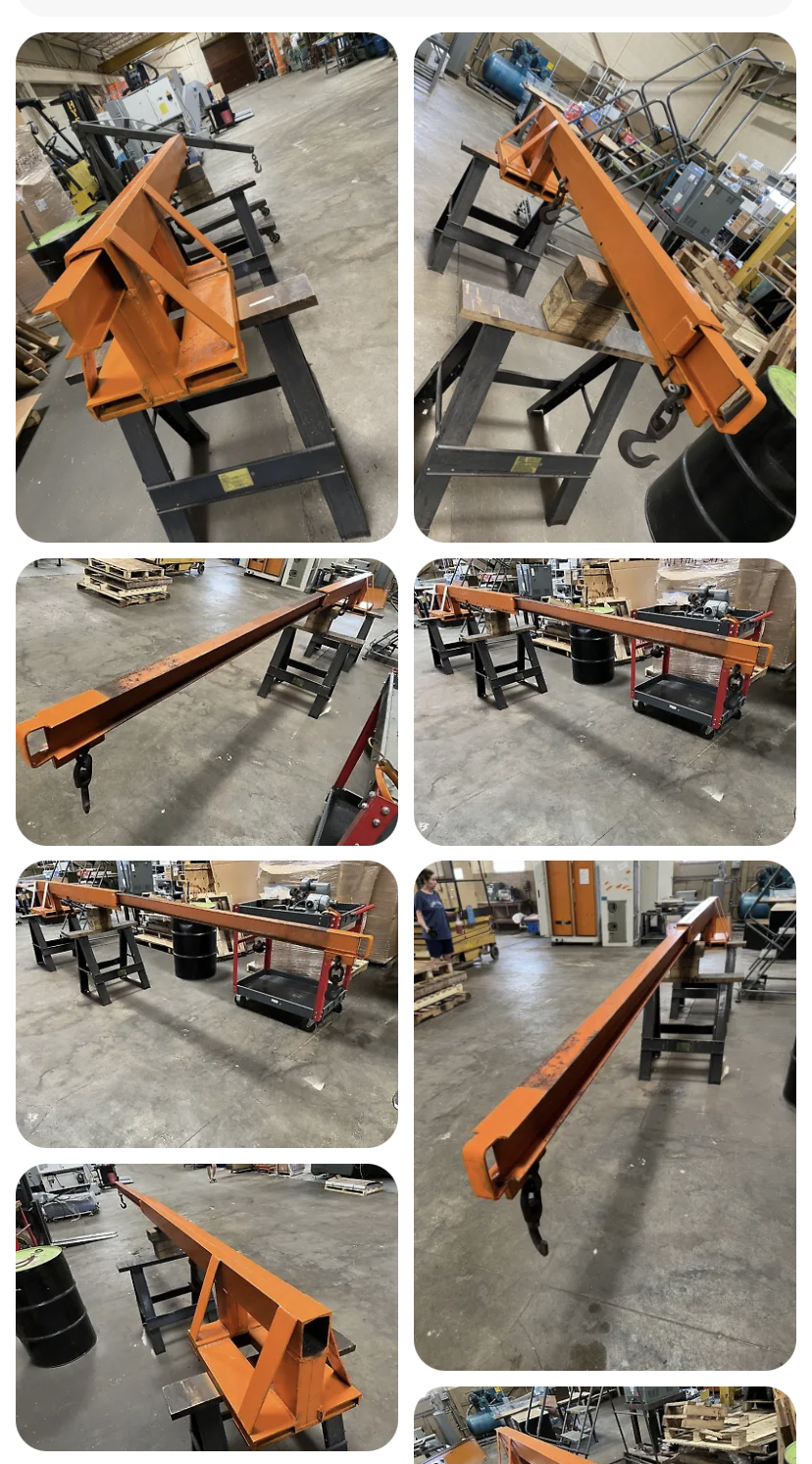

Forklift extensions are specialized attachments designed to increase the reach of standard forklift forks. These extensions can help in handling larger loads efficiently, particularly in warehouses and construction sites where space is at a premium. By extending the length of the forks, operators can lift and move items that would otherwise be difficult to manage with standard-sized forks. This enhancement not only improves productivity but also enables the handling of loads that require a wider or longer support.

Using forklift extensions comes with benefits, but it is essential to understand their limitations. Not all forklifts are compatible with every type of extension, and using the wrong combination can lead to safety hazards and equipment damage. It is crucial to select extensions that are rated for the specific forklift being used, as well as to follow manufacturer guidelines regarding load capacities. Additionally, proper training on how to use these extensions is necessary to ensure the safety of operators and those working nearby.

Maintaining forklift extensions is as important as proper usage. Regular inspections for wear and tear, as well as checking for any potential damages, should be a standard practice. Rust and corrosion can affect the integrity of the extensions, making them unsafe for use. Ensuring that extensions are properly fitted and secured before operation is also vital to prevent accidents, which can lead to serious injuries and significant costs. By understanding these aspects, operators can maximize the benefits of forklift extensions while ensuring a safe working environment.

Types of Forklift Extensions

When it comes to forklift extensions, there are several types designed to meet various operational needs. Standard fork extensions are the most common type, which simply increase the length of the existing forks. These extensions are ideal for handling longer loads that may not fit comfortably on standard forks. They are easy to install and remove, making them a versatile option for many warehouse and construction applications.

Another type is the heavy-duty fork extension, which is built to support significantly larger and heavier items. These extensions are typically constructed from thicker steel to enhance durability and strength. Heavy-duty extensions are essential for industries that frequently deal with oversized materials and require a strong, reliable solution to ensure safety during transportation.

Lastly, there are tapered fork extensions, which feature a design that narrows towards the tip. This type of extension is particularly useful for lifting pallets or boxes that are difficult to maneuver. The tapered design allows for better access in tight spaces and provides enhanced grip on the load. Choosing the right type of forklift extension not only improves efficiency but also ensures the safety and security of the items being handled.

Benefits of Using Forklift Extensions

Forklift extensions offer significant advantages by increasing the lifting capacity of standard forklift tines. This expanded reach allows operators to easily handle larger pallets and heavier loads without the need for specialized equipment. By effectively maximizing the lifting height and width, businesses can enhance their material handling capabilities, streamline operations, and reduce the risk of damage to products.

Another key benefit is the cost-effectiveness of forklift extensions. Instead of investing in additional forklifts or larger machinery that may not be utilized at all times, companies can opt for extensions that are compatible with their existing fleet. This not only saves money but also minimizes storage space, as extensions can be removed and stored when not in use. Additionally, they can improve productivity by enabling quicker loading and unloading processes, which can lead to increased efficiency in the overall supply chain.

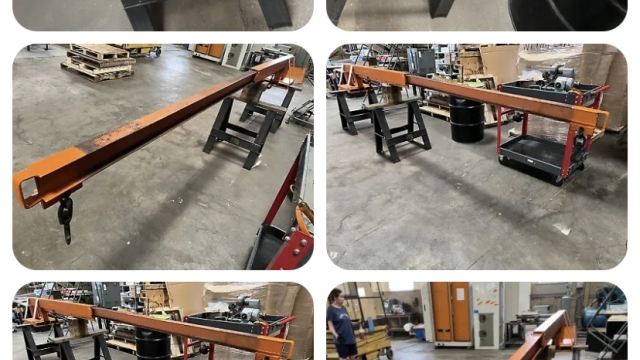

Forklift Extension Forks

Safety is also a critical aspect that is improved with the use of forklift extensions. By extending the reach, operators can lift and maneuver materials more effectively while maintaining stability. This leads to a reduced risk of accidents and injuries on the job site since extensions provide better support for oversized loads. When used properly, forklift extensions enhance both the safety and reliability of material handling operations, making them an invaluable addition to any warehouse or distribution center.

Installation and Safety Tips

When installing fork lift extensions, it is essential to carefully read and follow the manufacturer’s guidelines. Ensure that the extensions are compatible with your specific lift model to guarantee proper fit and functionality. Begin the installation process by securely mounting the extensions onto the fork tines, making sure that they are evenly adjusted to avoid imbalance. Double-check all connections and ensure that safety locks are engaged to prevent any accidental dislodging during operation.

Safety should always be the top priority when using fork lift extensions. Operators must be trained and familiarized with the extended load’s weight limits and stability. Before lifting any load, conduct a pre-operation inspection of the extensions and the fork lift. Check for any visible wear or damage that could compromise safety. It is vital to operate the lift at a reduced speed while carrying wide or extended loads to maintain control and maneuverability.

In addition to proper installation and operation, always ensure that your work environment is safe. Keep the area clear of obstacles and ensure that ground surfaces are stable. Use spotters if necessary when maneuvering large loads in tight spaces. Adhering to these safety tips will not only protect the operator but also prevent damage to the fork lift and extensions, ensuring a more efficient lifting operation.